MFTBC to companion with True 2 Supplies Pte. Ltd. (T2M) on pilot facility for recovering anode, cathode and electrolyte supplies from EV batteries

Mitsubishi Fuso Truck and Bus Company (Headquarters: Kawasaki Metropolis, Kanagawa Prefecture, President and CEO: Karl Deppen, hereafter “MFTBC”) will construct a take a look at facility for recovering supplies from used electrical automobile (EV) batteries at its Kawasaki Plant, in partnership with True 2 Supplies Pte. Ltd (Headquarters: Singapore, CEO: Richard Carlow, hereafter: T2M). Beginning in 2025, the businesses will use the pilot plant to guage the reusability of anode, cathode, and electrolyte supplies by battery cell makers.

The variety of used EV batteries is predicted to extend as demand for EVs expands amid international traits in the direction of decarbonization. Used EV batteries will be reused for different functions as they’re, or they are often recycled to obtain uncooked supplies and elements for different merchandise. Via the assessments collectively with T2M, MFTBC will contemplate a enterprise enterprise that recycles used batteries from EV vehicles, comparable to its electrical light-duty eCanter, and EV passenger automobiles, into compounds that may be straight used as high-quality blended supplies in battery cells.

MFTBC will first contemplate commercialization in Japan and examine the potential for abroad enlargement sooner or later. Whereas batteries account for a big a part of an EV’s price, MFTBC intends to maximise the worth of battery supplies by growing efficient retreatment processes, and thereby decreasing the entire price of EVs. The corporate goals to ultimately create an surroundings the place prospects can simply transition to e-mobility choices.

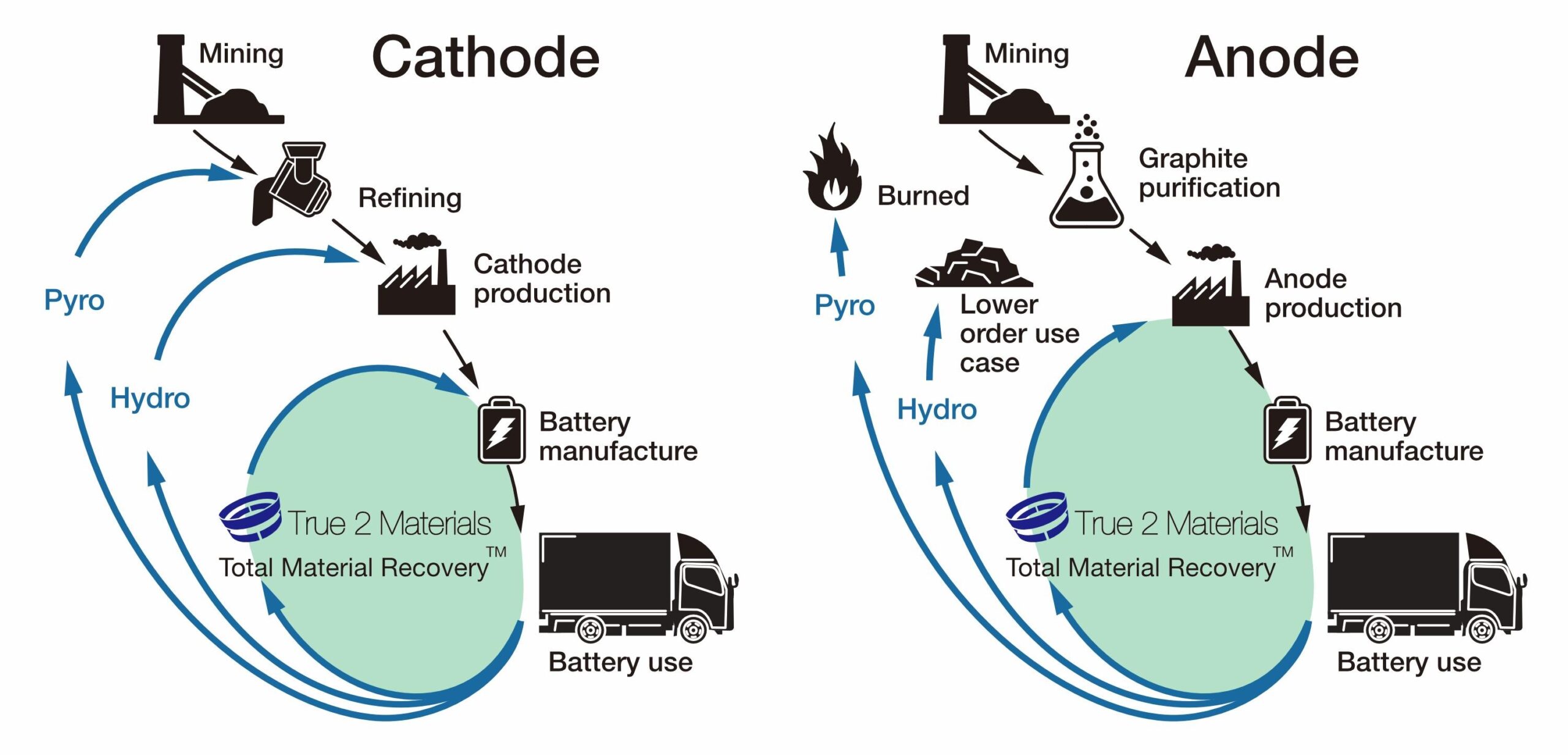

T2M has developed Complete Materials Restoration (TMR), a expertise for processing used and scrap batteries into usable anodes and cathodes whereas minimizing lack of uncooked supplies and their worth and decreasing environmental impression. The TMR course of makes use of nano-level molecular methods and is totally different from typical pyrometallurgy and hydrometallurgy battery recycling. The expertise permits restoration of as much as 99.9% of all EV battery sources, a better share than typical strategies, thereby maximizing battery useful resource worth. This novel course of additionally tremendously reduces the quantity of CO2 and different emissions, decreasing the environmental impression of disassembly processing. As well as, it’s anticipated that the price of steel processing, which usually accounts for practically 75% of the price of your complete recycling course of, can be considerably lowered.

This initiative is a part of MFTBC’s FUSO eMobility Options framework to assist prospects’ EV shift. MFTBC will proceed to develop services and products that contribute to realizing carbon neutrality by 2050.

Cycles of anode and cathode elements for EV batteries

SOURCE: Fuso

Comments